Author Archives: admin

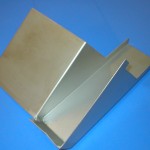

Custom Metal Fabrication Services

Whether you belong to an industry that needs specific tools in order to keep going or want to get a product out to your customers, you’re going to need quality materials, excellent design, and a company that you trust to meet your deadlines. Because your job is industry-specific, it might seem difficult to find a metal fabrication company that can meet all those standards.

Fortunately, Metal Force is a quality metal fabrication company that is dedicated to helping clients across a variety of industries get the tools and products they need, no matter what the specifications are. We excel with custom projects and stick to our deadlines better than many others in the industry.

Many Industries Require Custom Metal Fabrication

Metal Force has served and continues to work with projects from a wide selection of industries. We provide the tools and products necessary to keep other companies running, and we would like to develop that relationship with you. Currently we can perform custom metal fabrication work for the following industries:

- Energy

- Government (US Navy)

- Structural

- Engineering and design

- Oil

- Mining

This list is certainly not comprehensive, and, if your industry does not appear here, we are always willing to accept new projects outside of these areas. Our expertise is wide-reaching, and it’s very likely that we can help you!

Quality Work Each and Every Time

There are two things that our clients value above almost everything else: quality and reliability. We understand that getting the right tools and/or products on time is crucial, so we make it a priority to meet every deadline. Additionally, we are only satisfied with the highest quality materials and work from our employees, so you can trust that everything will look and work perfectly every time.

If you’re interested in talking to Metal Force about a custom metal fabrication services, call us today at (801) 776-5700

Meeting Your Metal Fabrication Deadlines

In the metal fabrication industry we often face concerns from customers about turnaround time and the ability to meet their productions deadlines. The ability to receive machinery or other equipment and have it installed and running in time to complete production on time is extremely important to our customers in order to be able to maintain productivity and profitability. Any delays could seriously impact the bottom line of our customers. We completely understand the urgency of each of our customers’ projects and the necessity of meeting sensitive deadlines. Our team of metal fabrication specialists is dedicated to each and every one of our customers to help them find the right solutions for their metal fabrication application in a timely manner.

Although we deal with many instances in which our customers have an emergency situation, there is one in particular we dealt with recently to help our customer comply with their deadlines. We were awarded a machining contract in Saudi Arabia that required our team to meet some very tight shipping deadlines. Although we had other projects to complete and customers to satisfy, there was a sense of urgency on this project that required us to meet these very strict deadlines. In order to accomplish all of our customers’ goals on an individual basis, our dedicated team of metal fabrication specialists worked around the clock until all deadlines were met and we were able to meet the very sensitive shipping deadlines for the contract in Saudi Arabia.

We would like to emphasize that although emergency situations arise for many of our customers, we never sacrifice the quality of work we do or the current projects of other customers in order to satisfy the needs of emergency situations. We offer uncompromising service and products to all of our customers. When we make a commitment to meet additional deadlines, we work diligently on our side of the projects to ensure that we are not sacrificing the needs of any one customer to meet the needs of another. Our team at Metalforce is fully invested in the quality, efficiency, and urgency of every project we take on.

We are happy to discuss meeting your metal fabrication deadlines and encourage you to contact Metal Force Inc at (801) 776-5700